Once upon

a time

A WORD

from our employees

The Team took on the challenge and successfully saw it through within a short one-year period.

An innovation strategy together with strong brands

In 2003, LIPHATECH inaugurated its production plant in Agen and began marketing its rodent control products to 3D professionals.

In 2006, it became the exclusive distributor of the SENTRI TECH termite control range for Dow France, and rounded out its range of ROZOL®, MAKI® and GENERATION® rodent control products by acquiring AEGIS®, a company specialising in bait stations design and production.

In 2013, LIPHATECH launched the NEORAMUS collaborative research Programme with the aim to develop new solutions for the future (active substance, new bait formulation, …).

With the recent launch of the BIAGRO® and LT KLEAN-AGRO™ brands for the agricultural and animal health market and FRAP® for non-professionals, LIPHATECH covers all markets in and outside France.

To safeguard a healthy environment by developing innovative and effective solutions, promoting good practices and limiting the environmental impact of our products.

A proactive

leader

We are confident in our position as an innovative market leader and as such we are committed to investing in Research and Know-how. Our mission and engagement is to design and manufacture the best products and services, by anticipating, listening, adapting to market needs, and respecting regulatory requirements, with respect to environmental issues and societal expectations.

LIPHATECH’s CSR* policy encompasses actionable initiatives such as significantly reducing its energy consumption, ensuring rigorous waste management, constantly optimising its working conditions and encouraging a collaborative approach with all employees.

Furthermore, LIPHATECH is ISO 9001 certified since 2002 and constantly strives for continuous improvement in its key production and business processes.

*CSR: Corporate Social Responsibility

Makingrodent control everyone’s business

As the market leader in rodent control, we embrace our social responsibilities and this is the reason why we go beyond solely manufacturing and selling products.

We invest in industry federations initiatives, in France as well as in Europe, to promote and to defend the industry by deploying all our energy to countering preconceived ideas.

In order to effectively fight against rodents, LIPHATECH develops educational tools to support professionals in their daily task consisting in the protection of our properties, resources and health.

Capitalcontrol

LIPHATECH as a member of DE SANGOSSE Group is a majority employee-owned company.

This very specific and original management model grants us a total freedom in our operations and allows maintaining a strong investment policy, especially with regards to Academic Research and the company’s industrial facilities.

The amounts budgeted each year (between 15% and 20% of total turnover regardless of the economic condition), to create new solutions and to modernise the plant’s equipment, help to ensure regular and sustainable growth.

The regulatorydepartment

LIPHATECH’s regulatory department exclusivly dedicated to biocides helps the company to successfully manage the whole regulatory process from the approval of active substances to national products registrations at worldwide level.

The regulatory department is involved in industry federations at an international level and undertakes all key actions on behalf of the industry. Today, LIPHATECH is recognised as a committed leader that places the interests of the industry ahead of its own interests.

Internationalscope

LIPHATECH has manufacturing-plants located in France and in the United States (LIPHATECH–Inc. Milwaukee) to cater for a worldwide product distribution. The Export Team strives to build balanced and long-lasting partnerships with companies sharing our vision. LIPHATECH current export turnover is over 35%.

LIPHATECH continuously contributes by sharing its expertise, developing a complete range of solutions, and providing them with good practices promoting tools.

As the global market leader, LIPHATECH is committed to ensuring that the products placed on the market comply with the regulations in force in each country.

COMMITED

to reducing our energy consumption

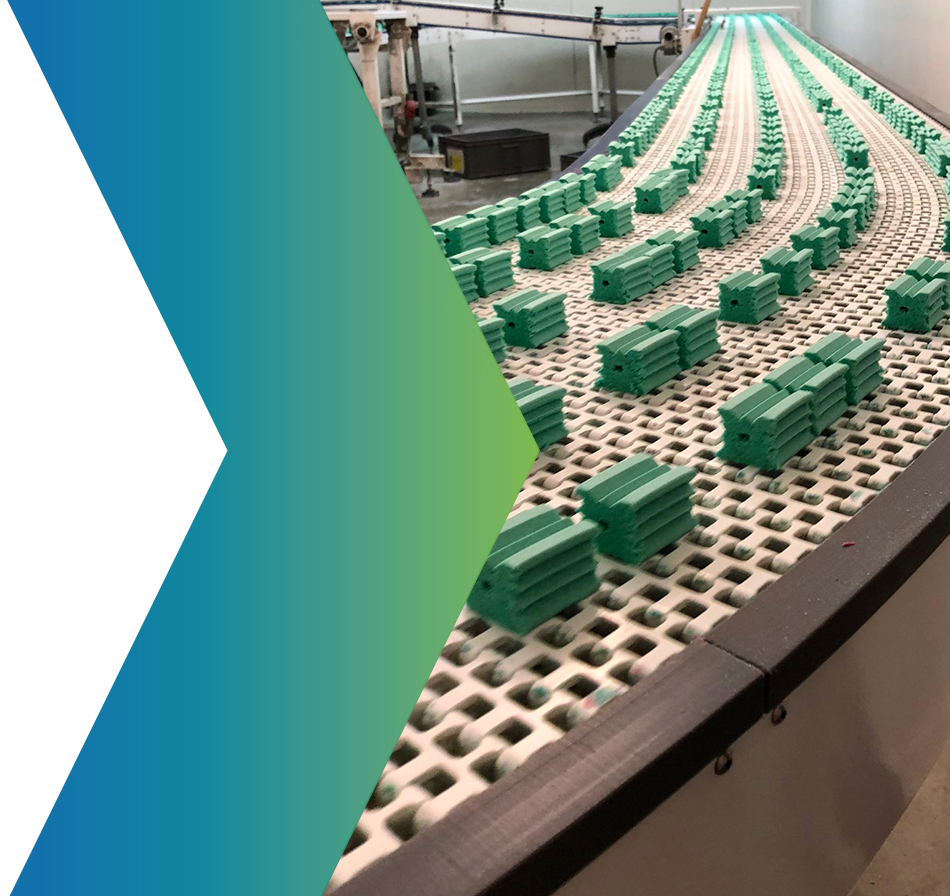

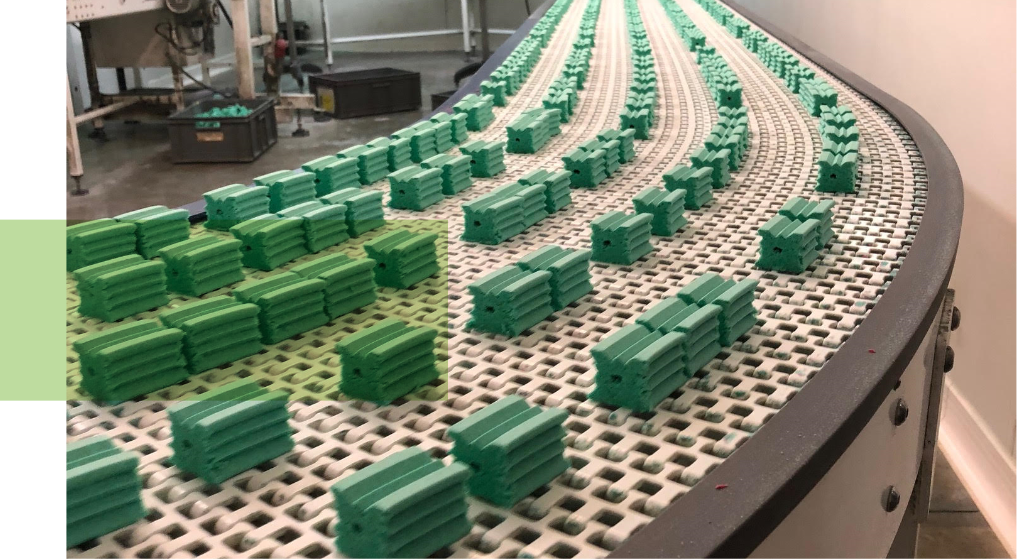

It’s a primary focus. In 2021, our industrial site switched to LED lighting. This enabled us to reduce our energy consumption by 50% – a saving of 100,000 kw/year – the equivalent of the average consumption of 25 households per year. On our block production line, our investment in a new variable output compressor, cooling system and conveyor has resulted in a 50 % reduction in energy consumption. Next step: the launch of an energy consumption audit on all Liphatech sites in order to identify new avenues for improvement.

COMMITED

to better working conditions

The “safety and workstation layout” commission – led by factory personnel meets regularly to identify areas for improvement. A tangible example: thanks to the multihead weighing machine, (cost 300K€), the paste production line works continuously from creation of the recipe to the final packaging. There are no longer any stressful and constraining line breaks for the line conductors.

COMMITED

to tomorrow

Since 2019, Liphatech has welcomed young people on apprenticeship or professional training contracts. We support them in their studies as well as in the identification of their career objectives.

Launched in 2020, the fablab WEFOUND is our innovation laboratory dedicated to equipment. Its start up style operation is unprecedented in the company. Open to all employees who wish to participate in a project, this collaborative space focusses on new technology.